UL Approved Cables

HELUKABEL offers a wide range of industrial automation products with UL Listed or UL Recognized approvals.

UL approvals for products are an important factor for machinery and equipment manufacturers, as they facilitate access to the US and Canadian markets. UL stands for “Underwriters Laboratories” and is an independent testing organization in the US, like the German VDE. The Underwriters Laboratories defines standards for electrical components and their fields of application based on the National Electrical Code (NEC, also known as NFPA 79) - the US safety standard for electrical installations. UL approvals are also recognized as safety standards in many other countries because of the stringent fire safety requirements of the NEC.

There are two types of UL approvals – UL Listed and UL Recognized. Inspectors are usually more familiar with UL Listed requirements, so it is easier for them to accept this label. They tend to memorize the standard and can therefore make quicker decisions during the approval process. For mechanical and plant engineers, this means time and cost savings because testing and approval costs are much lower. The UL Recognized mark, in turn, includes hundreds of Appliance Wiring Material (AWM) styles found on the UL Identification Card. The UL ID card identifies the manufacturer's existing AWM styles.

The UL Recognized approval process begins when the product for a wiring device or machine, for example a cable, is submitted to UL. The product is sent with information on the application, such as voltage level, flame retardancy properties and temperature ranges. UL staff will then test the mechanical properties of the product and if it meets the required parameters, it will be granted an existing AWM style. If the requirements are not met, a new AWM style is issued. Approval can be challenging because there are many AWM styles, and the inspector cannot directly determine the class of the product. Determining the correct class requires further testing, which can take a long time. In addition, during the testing process, the inspector may come across a criterion that prevents acceptance. In this case, the customer must adapt the product and reapply for approval.

Customers may not be aware of the requirements that their applications must meet or the different installation options offered by North American suppliers. Due to the complexity, it is recommended to use UL Listed cables wherever possible.

In Case of Doubt, Select UL Listed

Buyers often choose UL Listed cable first, because the cable standard is easier to verify and can be approved more quickly. Once the product meets the UL Listed standard, the inspector is on the customer's side because they don't have to do the AWM studies. AWM styles should only be explored when a suitable UL Listed cable cannot be found.

Europe Focuses on the Materials Used in the Cable, While the USA Concentrates on Flame Retardant Properties

North American and European approvals are not always aligned. Many elements have become involved over time and there are many ways of looking at the situation. In European approvals, attention is paid primarily to the materials used in the cables, such as the number of high-risk plasticizers or lead-free products. Cables installed in buildings must be halogen-free and/or have low smoke density or low toxicity characteristics. However, flame retardancy properties are the priority for UL certification.

UL Listed Data Cables

Data cables are described in UL Standard 444. Depending on the application and flame retardancy requirements, the individual chapters list the CMP, CMR, CM, CMG and CMX standard allocations according to the respective data cable criteria.

CM or CMG UL Listed (bundled fire test) as well as AWM style UL Recognized (individual vertical or horizontal fire test) versions apply to PVC-jacketed cables. The same applies to Flame Retardant Non-Corrosive (FRNC) versions. CMX UL Listed or UL Recognized versions are applicable to PUR jackets.

Cables with polyethylene (PE) jackets for outdoor or underground installations have no flame retardancy properties and are therefore not UL certified. In terms of flame retardancy properties, PUR can never satisfy a bundled fire test, however this material has good chemical and mechanical resistances. In cable track applications, this cable has a significantly longer service life than PVC-based materials.

HELUKABEL UL Approved Cables

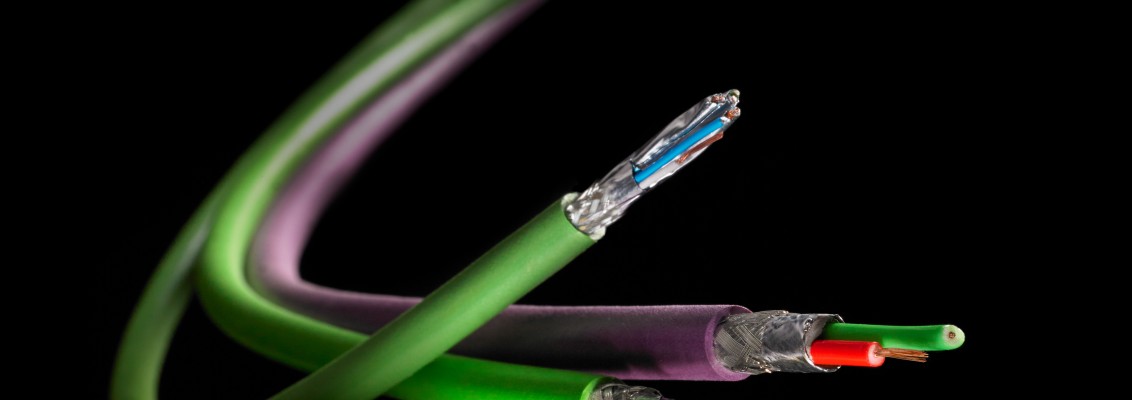

HELUKABEL offers a wide range of industrial automation products - control, VFD/servo motor, data, network, and bus cables with UL Listed or UL Recognized approvals. The company's global reach ensures customers that industrial machinery built in Europe or Asia to be exported to North America can be equipped with the required UL/CSA cables and wires.

The challenges faced by modern cables and wires are multifaceted: moving applications with more than 10 million cycles, exposure to extreme mechanical and chemical loads, tricky bending radii, and space-saving hybrid solutions, for example. HELUKABEL offers solutions for every situation. To ensure that no problems occur during use, all newly developed products are carefully tested at the HELUKABEL Research and Development Centre in Windsbach, Germany. At the R&D center, cables are tested in every possible way, including bending, pulling, fire, and abrasion tests. The products are tested according to national and international standards, after which all results are signed and sealed.

Find out more about HELUKABEL's range of cables with international approvals.